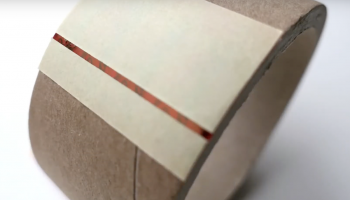

The LabelLink® splicing procedure connects label webs in the form of an overlapping splice. This creates a smooth transition with no uneven bumps in the label web and also ensures that the spacing between labels is unaffected by the join.

All that is necessary is for your label manufacturer to affix the LabelLink®splice tape to the core of your label rolls before winding the label web around it.

Label manufacturers worldwide order the LabelLink® splice tape from Verpackungstechnik Jetter GmbH.

When the end of label roll is reached, the LabelLink® splice tape is torn off the roll core and stuck onto the siliconized upper side of a new label roll in the space created by removing the first label.

The label web splice is fully automated and takes place within a specially designed splice head. Two different methods are available: the LabelLink® splice head or the JetSplice® splice head.